Screening,

Engineered for Reliability

Designed in weeks — not months

Simaflex Engineering

We know that every screening component — from spray systems to screen panels and chutes — should do more than meet specifications or tick a box. We show you how to reduce moisture, prevent material binding, and improve plant availability, while operating consistently from shutdown to shutdown.

We partner with clients who expect more from their screening process. We don’t just supply parts — we design with intent, engineer for reliability, and deliver integrated systems that improve performance across the entire screening circuit.

Core Product Categories

Engineered spray systems that maximise plant availability, reduce material carry back, and enhance screening efficiency — from shutdown to shutdown.

- Custom Spray Bars: Designed for screen decks, chutes, and conveyors to suit dust suppression, fines washdown, and lump screening.

- Nozzle Selection & Layout Design: Based on flow rate, pressure, spray angle, and material type.

- Trigger-Based Spray Control: Sensor-integrated systems with optional PLC connectivity.

- Modular & Retrofit Design: Fit-for-purpose units designed to suit existing infrastructure.

Key Benefits:

- Reduced downstream deadweight

- Reduced material blockages and screen blinding

- Reduced downstream load on conveyors and dewatering processes

- Improved ore presentation and screening separation

- Reduced manual hosing and labour costs

- Increase in plant availability

Purpose-built screening equipment designed for effective material separation in high-moisture environments — improving efficiency, availability, and ore presentation.

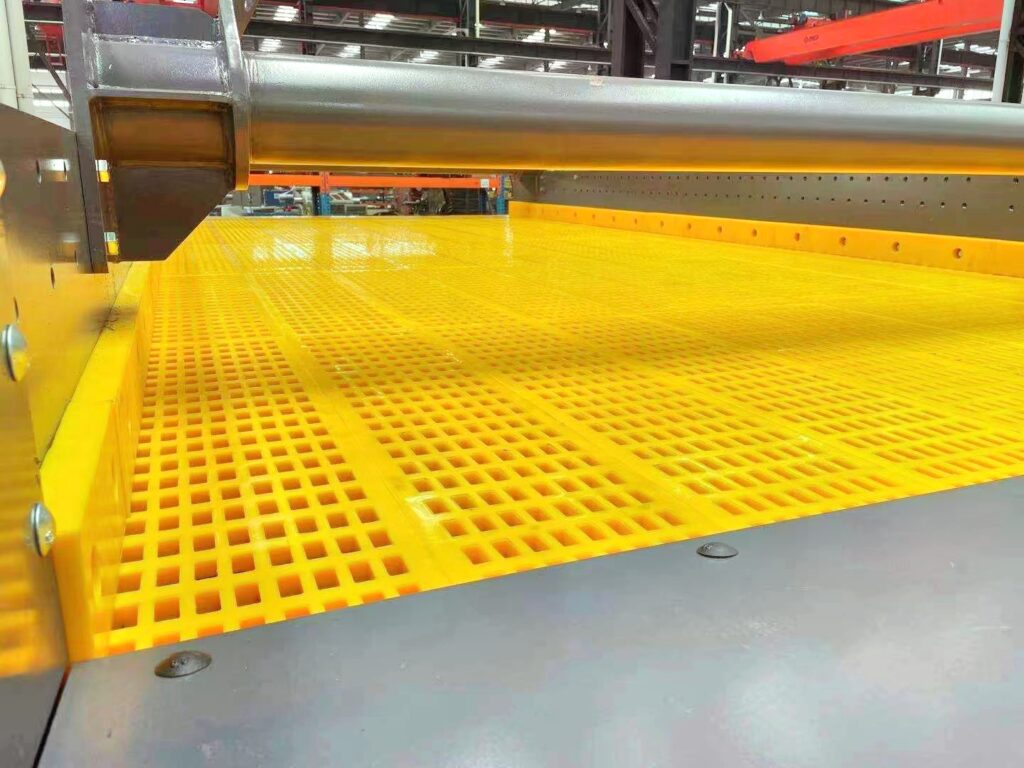

- Modular PU & Rubber Panels: For vibrating screens, in standard or custom formats.

- High-Performance Polymers: Designed for wear, impact, and reduced pegging.

- Custom Apertures & Configurations: Tailored to suit ore type and motion characteristics.

- Mounting Systems: Supports pin-and-sleeve, bolt-down, and snap-in configurations.

Key Benefits:

- Improved classification of fines and lump

- Enhanced throughput in wet processing circuits

- Reduction in screen blinding and cleaning frequency

- Custom apertures designs for target particle size distribution

- Compatible with integrated spray systems for maximum efficiency

- Shut-to-shut performance with optimised maintenance intervals

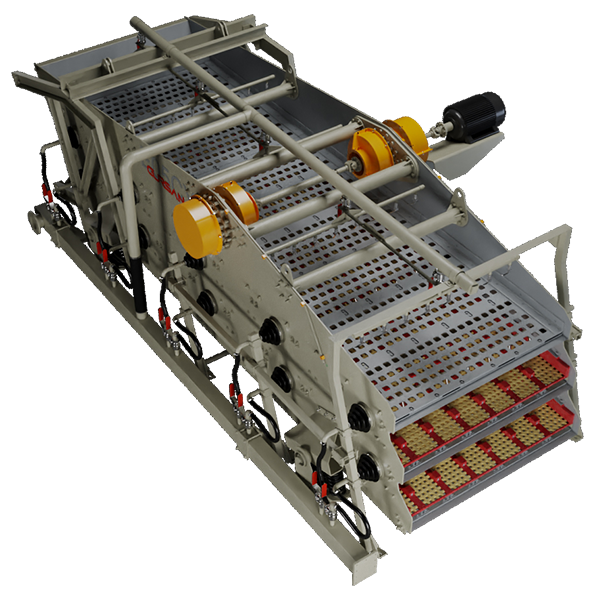

High-performance screening cassettes engineered to maximise throughput, minimise oversize, and deliver consistent material separation — without water.

Heavy-Duty Screen Cassettes: Built for dry classification, scalping, and crushing circuits.

Open Aperture Designs: Maximise cut efficiency while reducing carryover and blinding.

Custom Deck Layouts: Suited for multi-deck vibrating screens and high-capacity dry applications.

Dust Control Options: Integrated side seals, covers, and chute interfaces to support dry plant compliance.

Mounting Systems: Supports pin-and-sleeve, bolt-down, and snap-in styles to match existing setups.

Key Benefits:

- Cleaner separation of target size fractions

- Reduced oversize and carry back into downstream circuits

- Lightweight yet durable construction for longer wear life

- Compatible with existing screen deck structures

- Designed to operate from shut to shut with minimal maintenance

Fast panel changeouts

Built for abrasive conditions

Engineered chute designs and wear protection systems that control material flow, minimise hang-up, and extend asset life — from shutdown to shutdown.

- Flow-Optimised Geometry Review: Identify blockages, dead zones, and wear areas.

- Custom Chute Redesign: Resolve flow bottlenecks, reduce liner wear, and eliminate material hang-up.

- Custom Wear Liners: Using ceramics, rubber and other composite materials – selected to match site specific abrasion and impact profiles.

- Integrated Spray Management: Combine mechanical and hydraulic flow optimisation.

Key Benefits:

- Smoother flow with geometry that reduces hang-up and blockages

Longer wear life with site-specific liners (ceramic, rubber, composite)

Less downtime via modular, easy-to-replace panels

Lower maintenance through targeted diverters and impact zones

Safer access with fewer manual interventions

Accurate fit using 3D scans or existing drawings

Higher throughput from consistent, obstruction-free flow

Coil and rubber springs matched to screen weight, stroke, and frequency

Custom spring sizes for retrofits or upgrades

Corrosion-resistant materials for harsh processing environments

Key Benefits

Improved screen stability and vibration isolation

Reduced structural stress on screen decks and support frames

Longer screen and spring life with proper load distribution

Lower noise and vibration transfer to surrounding plant areas

Fit-for-purpose spring selection based on load, travel, and duty cycle

Minimal downtime with direct replacements or upgraded options

Engineered solutions that optimise the direction, velocity, and spread of material across screening decks — delivering cleaner separation and higher screening efficiency.

Flow diverters and spreaders to evenly distribute material across the screen width

Velocity curtains and deflectors to control feed speed and impact angle

Custom flow control features designed to reduce loading imbalances and oversize carryover

Key Benefits

Improved screening efficiency through uniform material presentation

Reduced screen blinding and pegging with consistent flow rates

Less oversize and misplaced fines from controlled impact velocity

Extended screen panel life by avoiding high-wear hotspots

Optimised throughput across the entire screen deck

Easier commissioning and tuning with tailored flow correction hardware

Key Projects

Reduced downtime and cut maintenance costs by replacing rigid spray bars with impact-resistant, flexible spray modules. Delivered longer operational life and improved screening performance with Simaflex-engineered solutions.

Conducted full root cause analysis on chronic screen blockages, leading to a 90% reduction in downtime, improved throughput, and the foundation for automated washdown systems.